Project Gallery

A few projects. Most of our projects are proprietary, so we can't share them. If you have questions about what we can do, drop us a line.

Custom Controls / Acquisition

Heater Control Panel

Heater Control Panel

A simple, four-zone heater panel satisfying NFPA requirements. A UL 508 project.

Wastewater treatment Smart Controller

Wastewater treatment Smart Controller

A collaboration between NorthStar Chemical and Interface Innovations, this project tackles a unique set of control problems for wastewater treatment, using NorthStar chemical products.

Automated testing and load bank panel

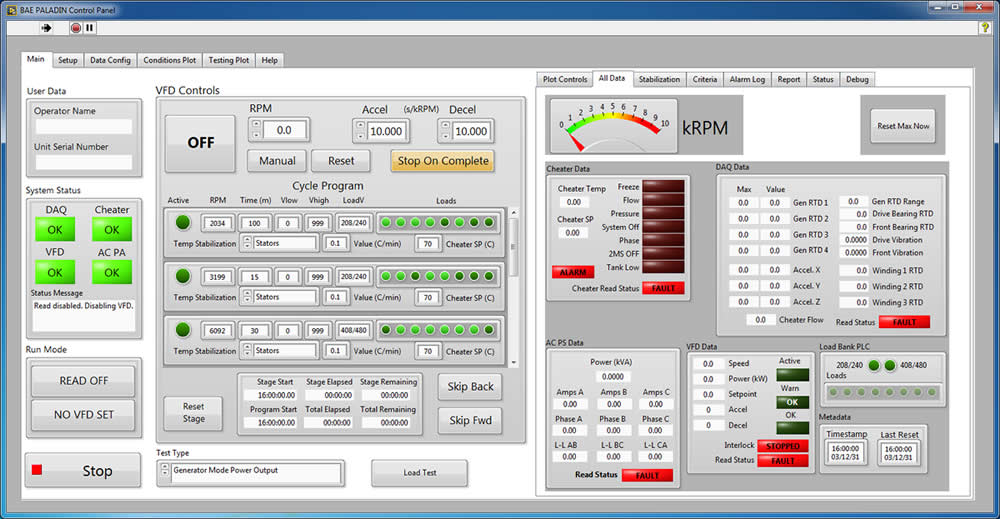

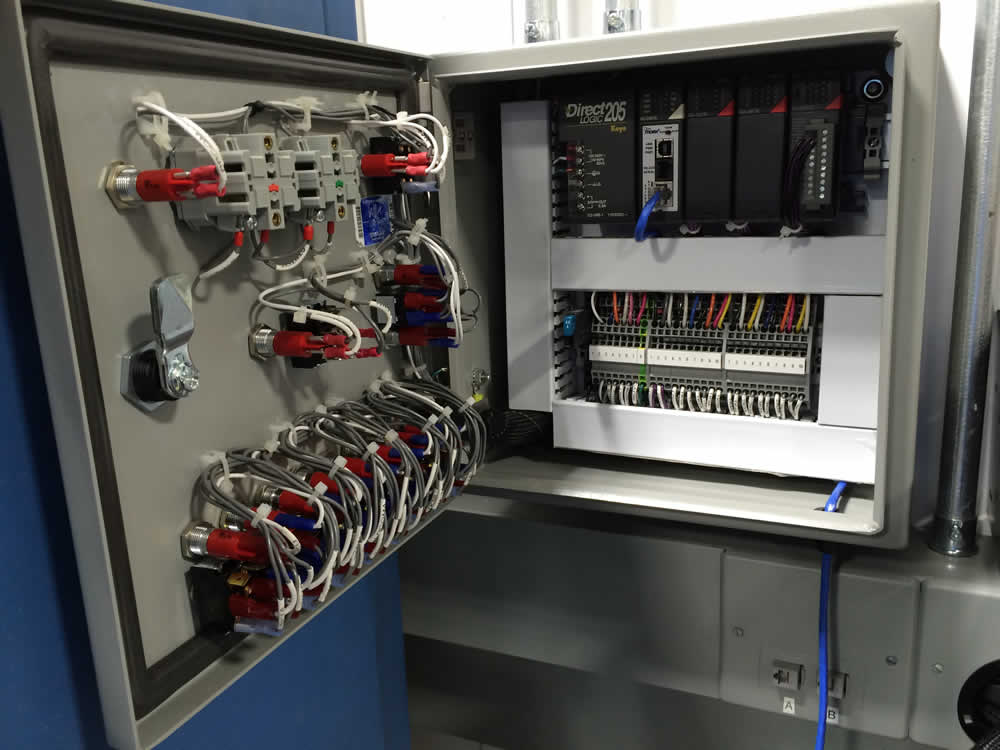

Load bank and automated equipment testing

This project wrapped up a wide variety of sensing and control technologies. Shown here is one of two control panels for monitoring and control of this system. The end-use application is proprietary.

The LabVIEW interface was a built executable that completed an extended, complex testing sequence with adjustable alarms and fault criteria for every variable recorded to data logs. The results of the testing were used for acceptance criteria for an external customer for the product.

A few details:

- Remote VFD control over Modbus TCP/IP with custom frame formats

- Nine RTDs read through custom driver board with filtering into analog inputs

- Three accelerometers read into analog inputs

- Two vibration sensors read into analog inputs

- Chiller flow rate sensors read into analog input

- Chiller/heater setpoint and monitoring over RS232

- Power supply monitoring over TCP raw socket

- Load bank control via control panel pictured, through PLC over Modbus TCP/IP

Solar module testing

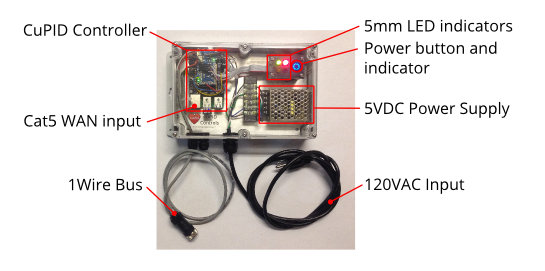

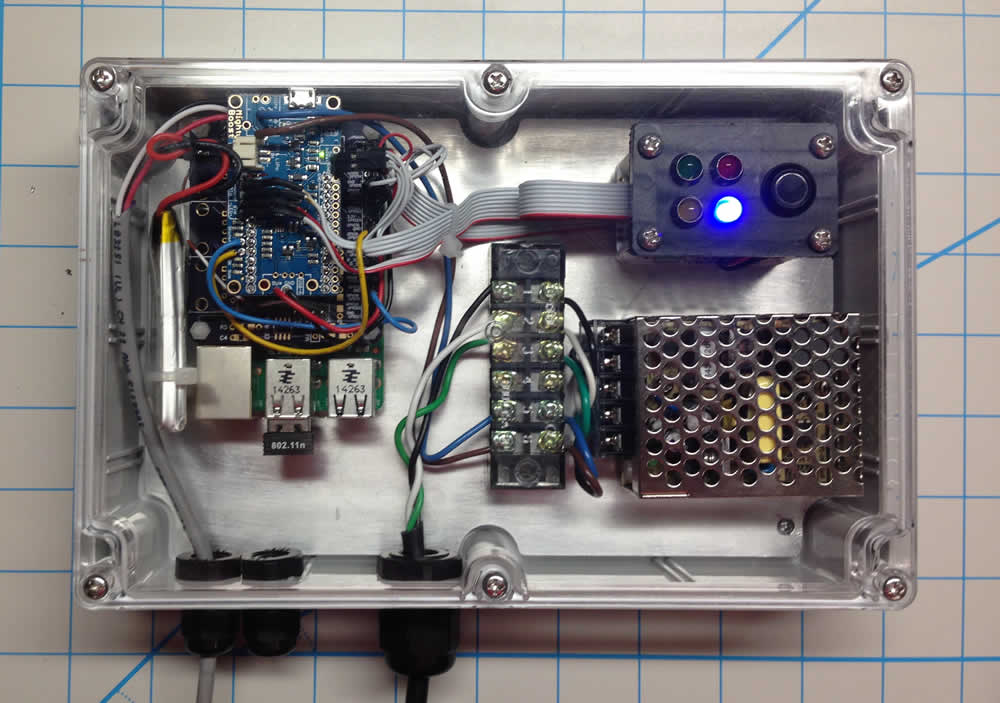

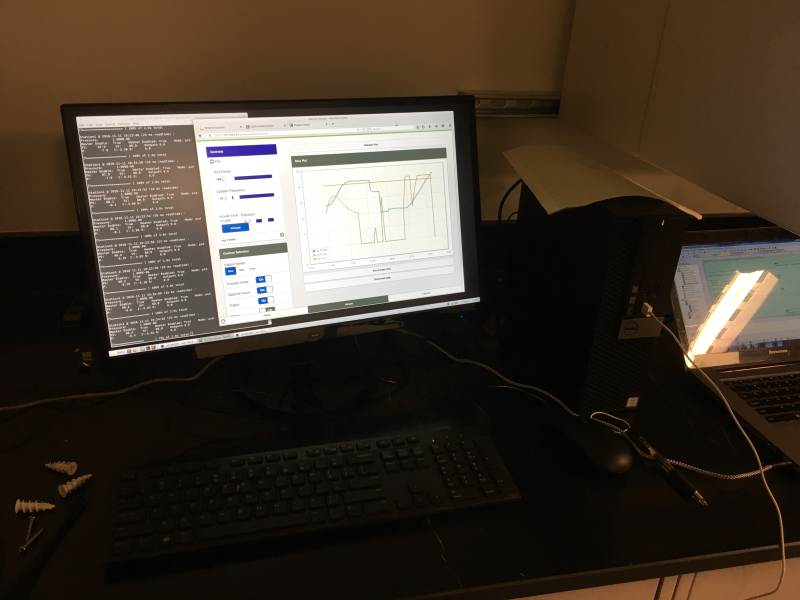

Remote temperature sensing and logging

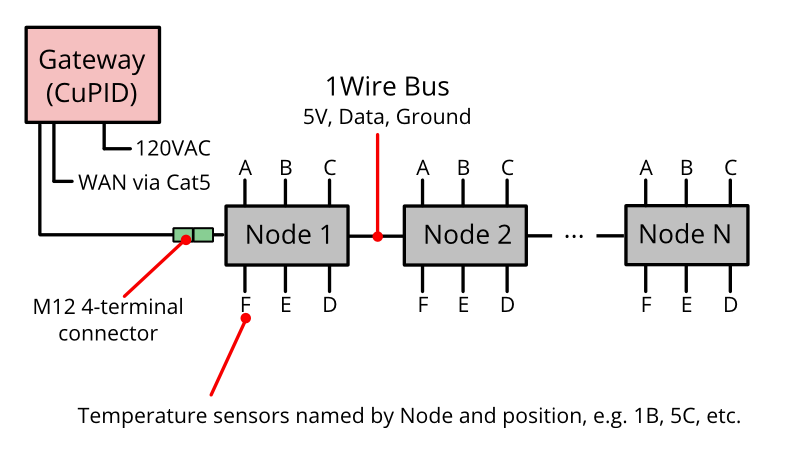

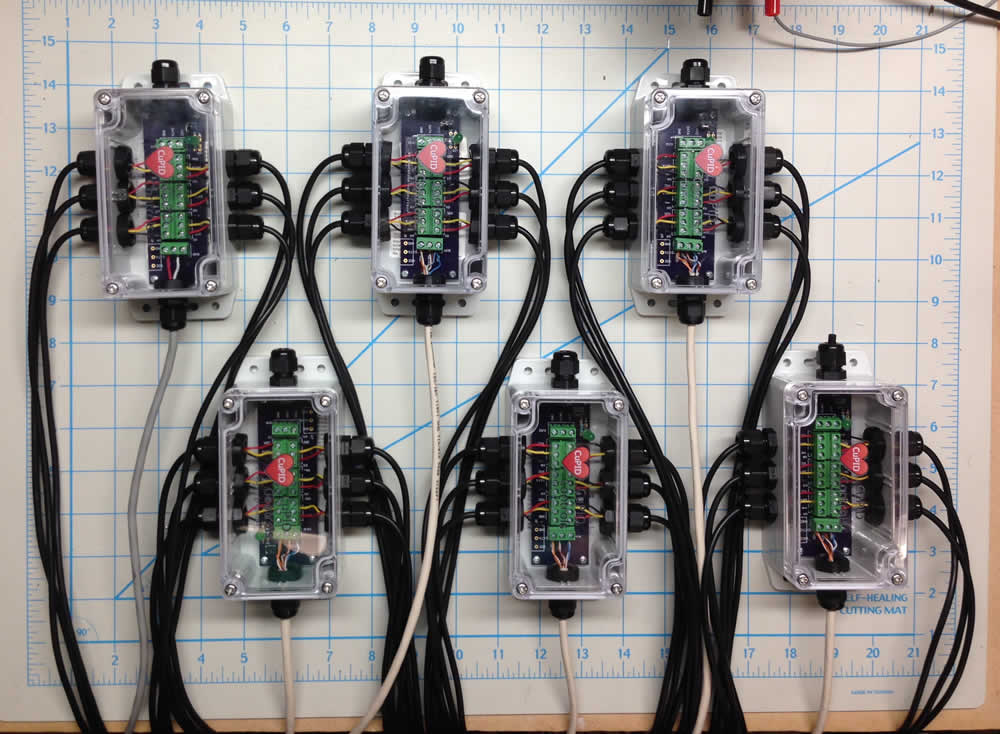

This project involved monitoring solar modules out in the wild. The temperature was logged continuously at six points per node, with the deployment here comprising six nodes for a total of 48 sensors. These were all on a single bus, utilizing the 1Wire protocol to transmit temperature data over three wires over a distance in excess of 100m.

The sensor gateway was connected via VPN for web-enabled view and access of data from anywhere in the world. On top of this, Interface Innovations is able to continuously update, monitor and troubleshoot system performance on-call. Feature requests and additions were addressed in real-time.

Anemometer and pyranometer were later added with a DAQ for read inputs. Standard iicontrollibs and cupidweblibs were used for this project.

A few details:

- 100% Web interface

- Built-in power management board with backup Lipoly battery for backup in power outages and graceful shutdown when necessary

- Bus extendable (nearly infinitely)

- Individually addressable temperature sensors with unique ROM identifiers

- LED indicator status lights for field service

- Waterproof sensors accurate to within 0.5C, precision selectable 9-12 bits

- RF communication is an easy optional add-on for remote sensors in this configuration

Automated Chemical Synthesis

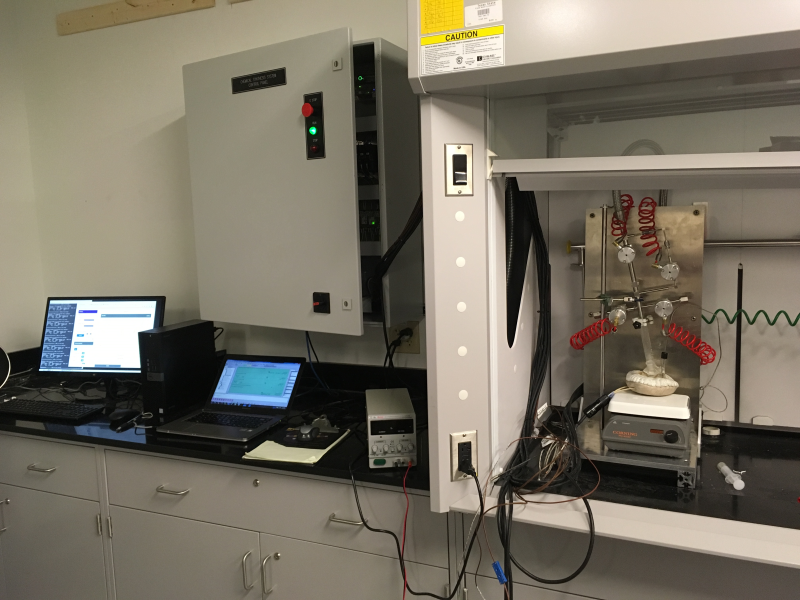

Automated Chemical Synthesis System

This project was a complete hardware and software solution for chemical synthesis of semiconductor nanocrystals.

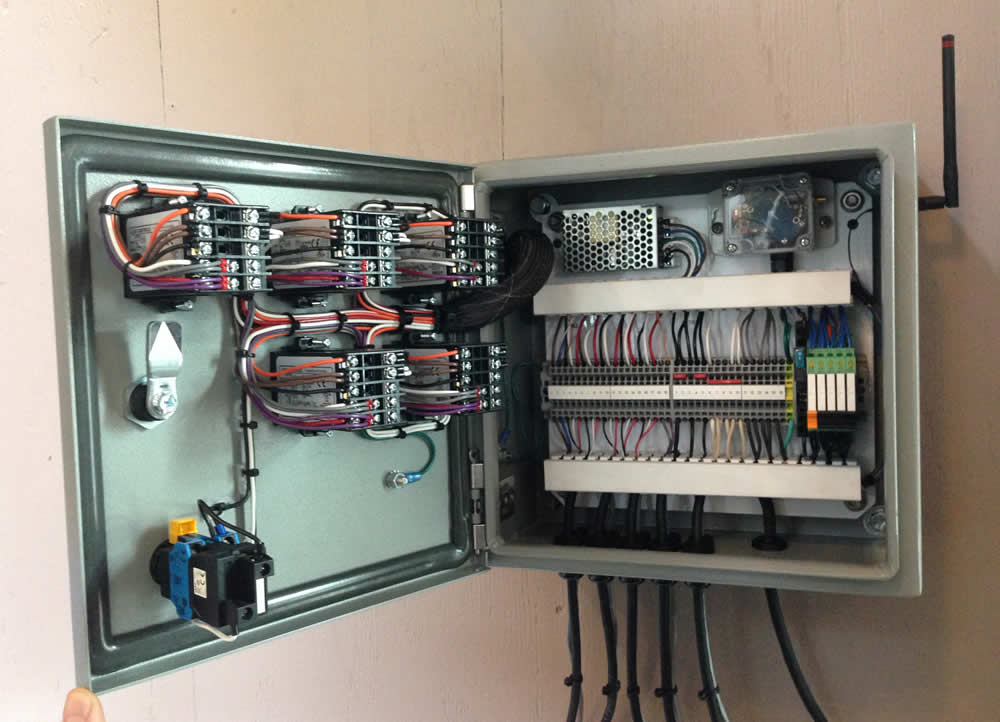

The control panel shown controls three synthesis control stations, each with four pneumatic valves, an SSR-powered heater with relay interlocks, monitored with four thermocouples. are read by a PLC, with heaters controlled by custom PID.

High-level control is handled by a scalable, object-oriented Python API that communicates with the PLC over Modbus TCP/IP. The API has hooks for a web interface, which was also provided, allowing for monitoring, logging and control of the synthesis tool from anywhere with a web browser.

Kegwasher Controllers

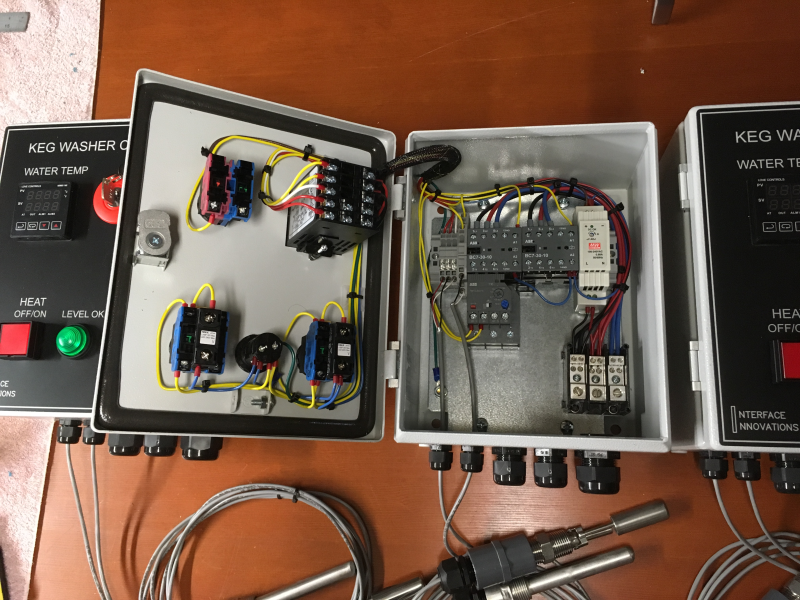

Simple OEM Kegwasher Controllers

This project began as a custom request and has turned into a regular production project for Practical Fusion LLC. Simple Stuff: Pump Output (contactor with overload), heating element output (contactor), with RTD temperature sensors and level float interlock on everything. All in a IP65 enclosure with a clean interface.

Brewery Projects

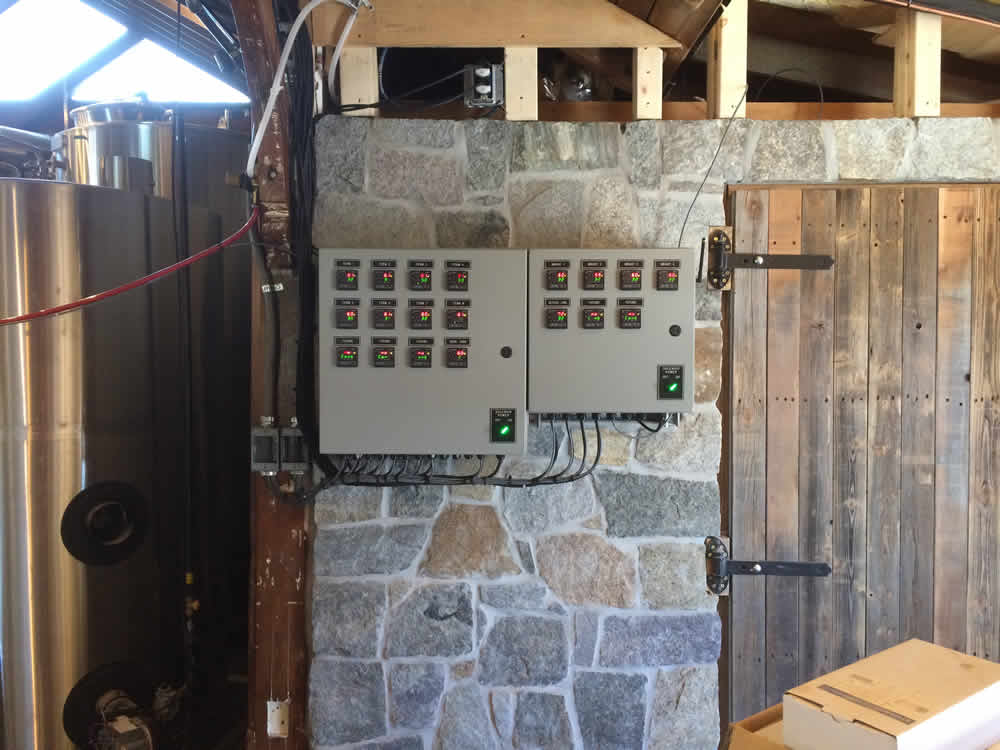

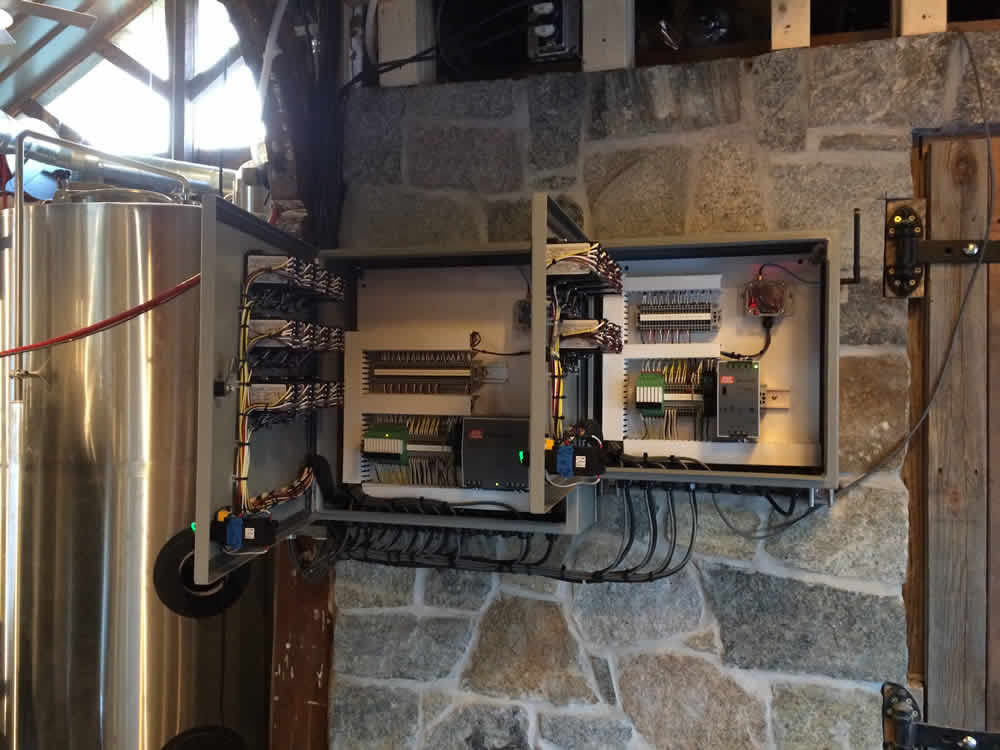

Garvies Point Brewing

Brewhouse control panel for Hammer and Stitch brewing. UL508a controls.

Obelisk Brewing

Brewhouse control panel for Hammer and Stitch brewing. UL508a controls.

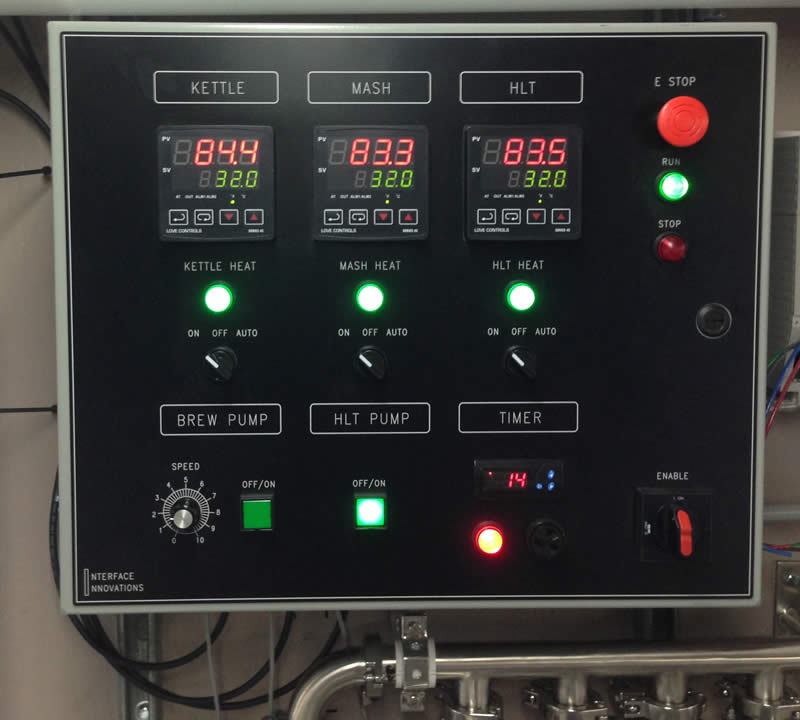

Hammer and Stitch

Brewhouse control panel for Hammer and Stitch brewing. UL508a controls.

Valdez Brewing

Brew and cellar control panels for Valdez Brewing.

Stemma Brewing

Cellar Panel at Stemma Brewing. Bellingham, WA. Seven vessels expandable to 14. 24x24 SS panel, 17" touchscreen and web UI.

Install 4/19

PFriem Family Brewers

Cellar Panel at Pfriem Family Brewers. Hood River, OR. Eleven vessels with dual inputs/outputs. Eight additional single input/output vessels, additional temperature inputs. 24x24 SS panel, 17" touchscreen and web UI.

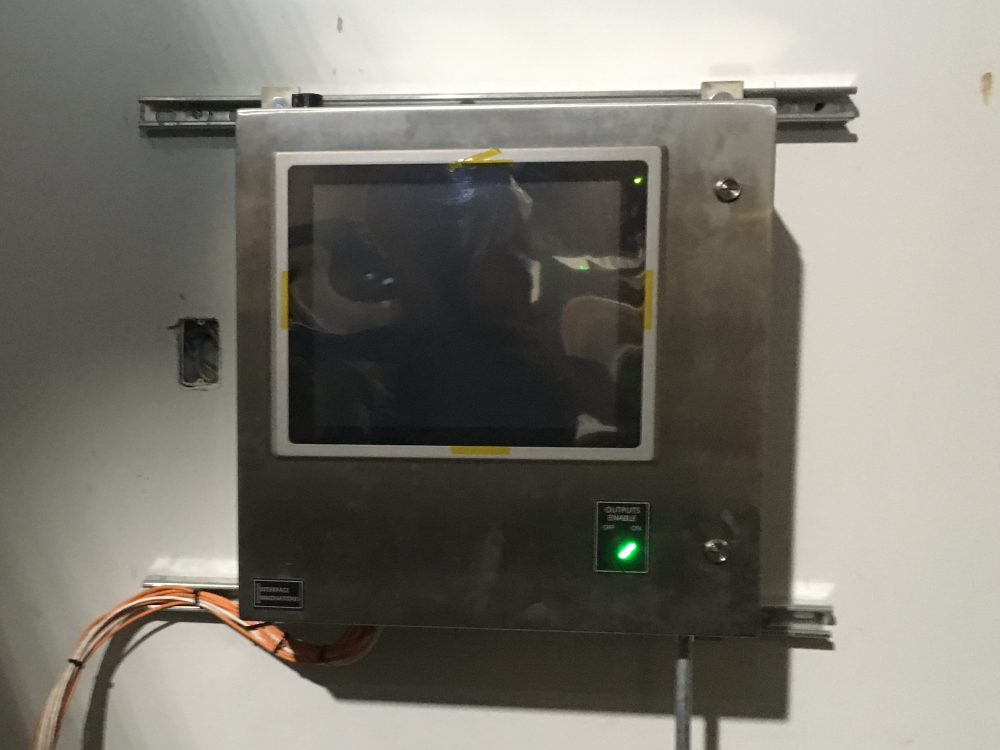

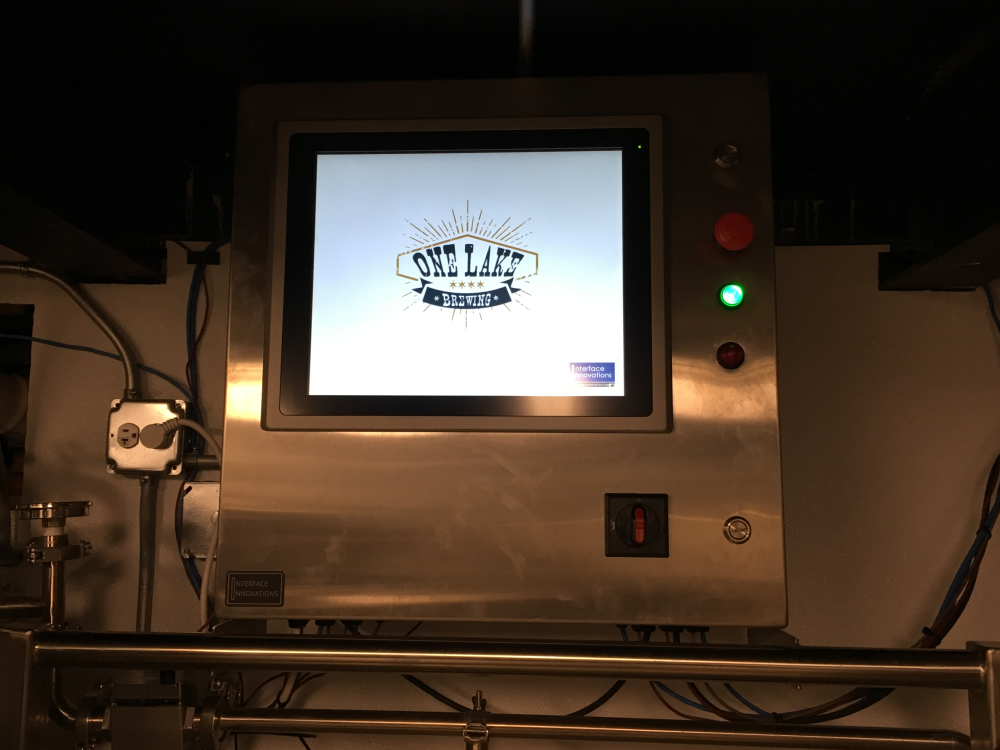

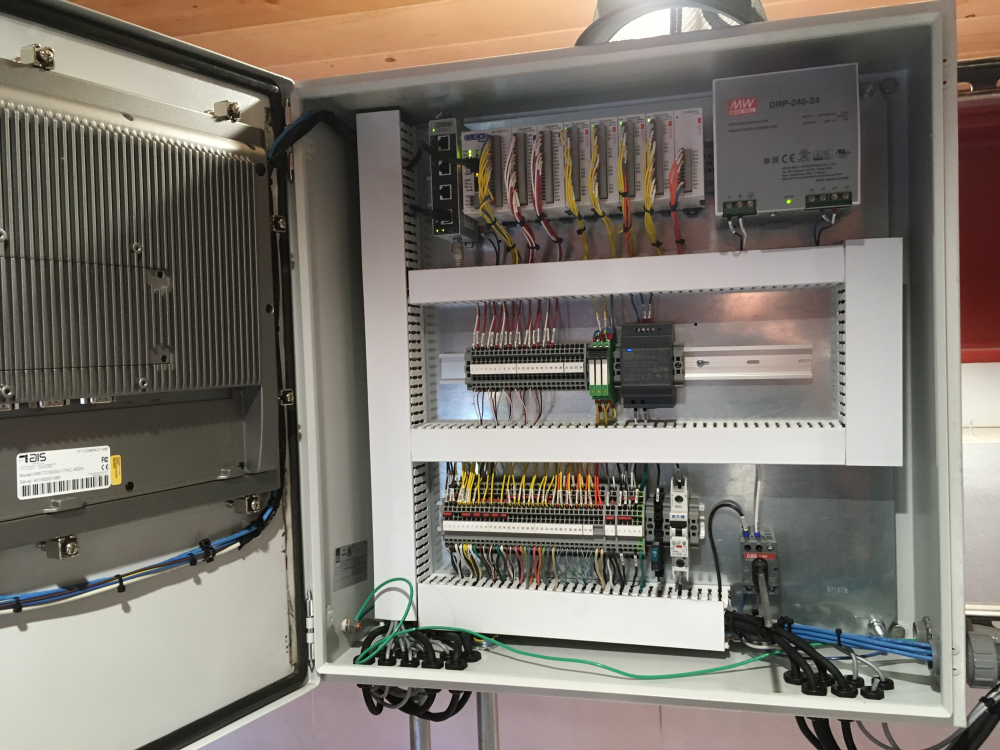

One Lake Brewing

Brew and Cellar Panels at One Lake Brewing, Oak Park, IL.

Brew panel: 24x24 SS, 17" Touchscreen, PLC. Two vessel control, four temperature inputs. Flowmeter integration and readout. HLT 60A Power Panel for Electric Heating elements.

Cellar Panel: 24x24 SS, 17" Touchscreen. Twelve vessel control. Web UI.

Walter Station Brewing

Brew and Cellar Panels at Walter Station Brewing, Phoenix, AZ.

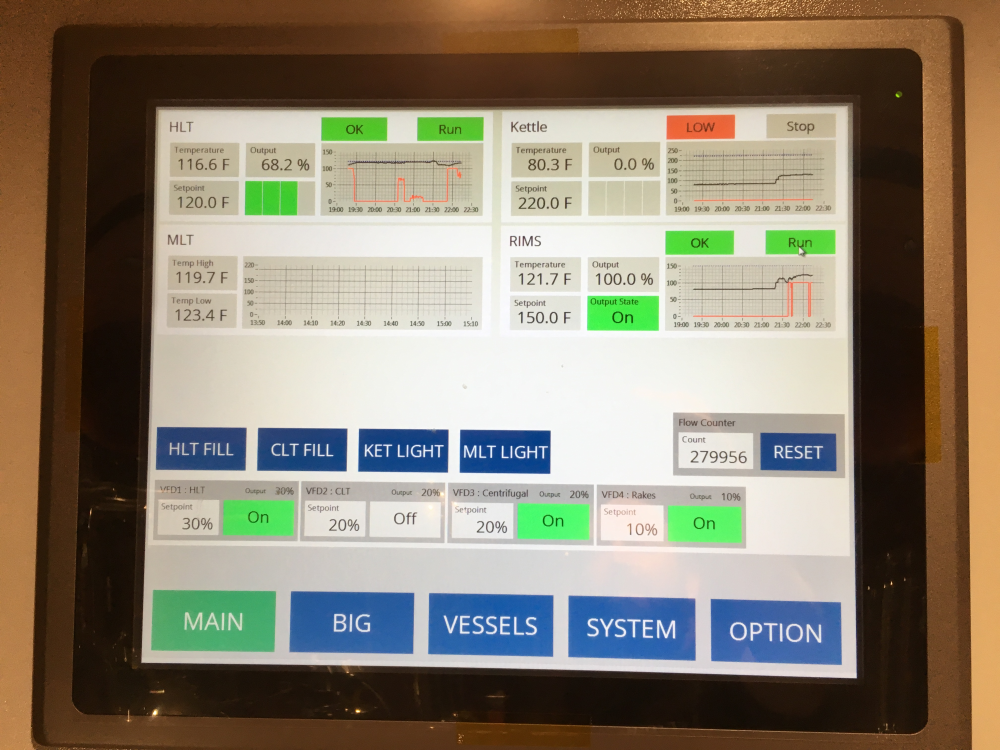

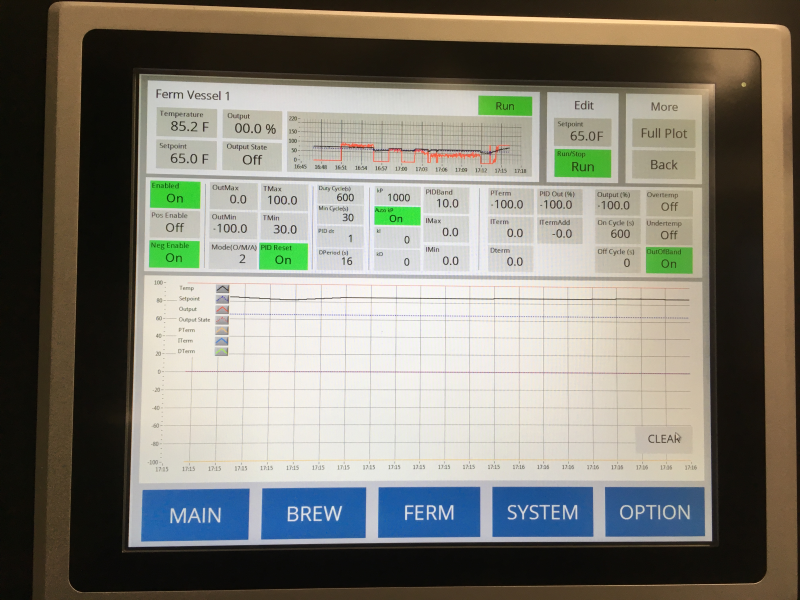

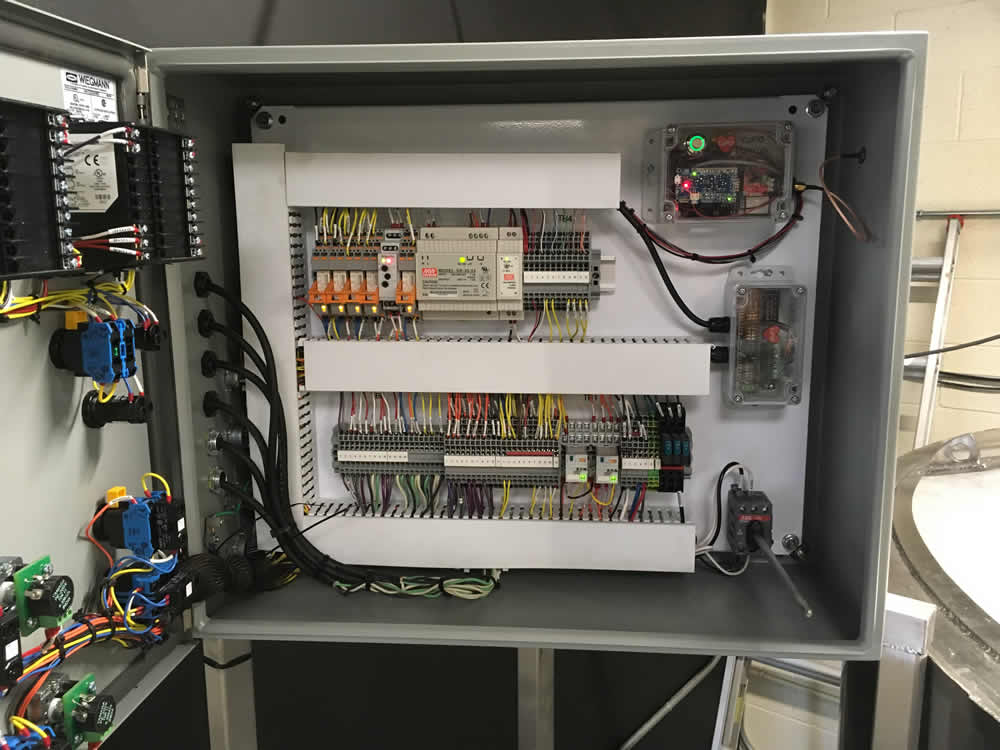

Brew panel: 24x24, 17" Touchscreen, PLC. HLT, Kettle, and RIMS control. Electric power panels for nine heating elements. Four VFDs, controlled from touchcreen UI.

Cellar Panel: 20x20, 10" Touchscreen. Twelve vessel control. Web UI.

Wayfinder Beer

Cellar Panel at Wayfinder Beer, Portland, OR. Ten vessels with 10" touchscreen and web UI. Expansion capability for ten additional vessels built in.

Vanished Valley Brewing Co

Brew Panel project at Vanished Valley Brewing Company, Ludlow, MA. Four brew vessels, three fermenters, one brite. 17" Touchscreen panel with network interface.

Lincoln Beer Company

Montavilla Brew Works

Brookeville Beer Farm

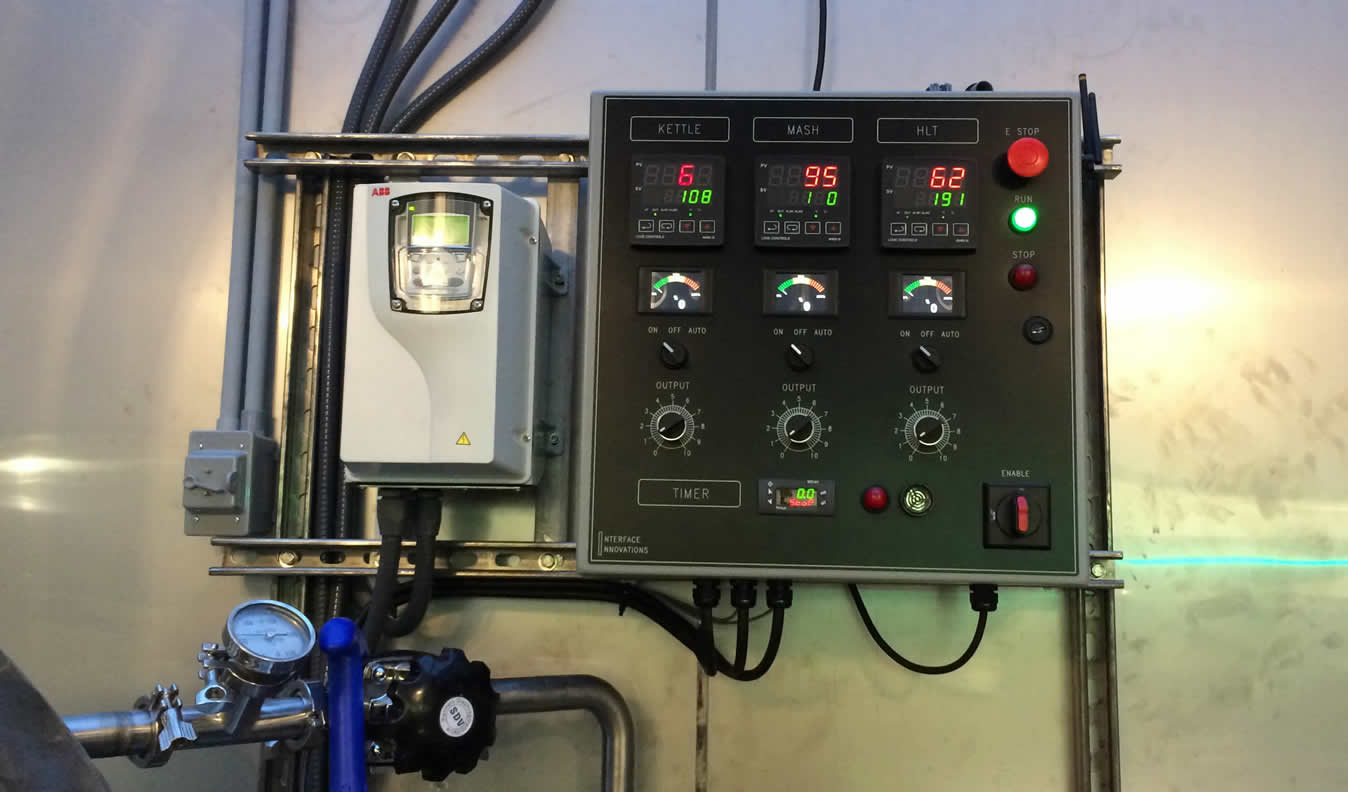

Yachats Brewing

Brew and Cellar Panel project at Yachats Brewing

This guy was a little bit different and interesting. Globe valves on steam with proportional output controllers. Miniature analog displays for output. Pretty cool.

Wastewater Treatment Controls

Pfriem Family Brewers

Heater Control Panel

A simple, four-zone heater panel satisfying NFPA requirements. A UL 508 project.

Reser's Fine Foods

Wastewater treatment Smart Controller

A collaboration between NorthStar Chemical and Interface Innovations, this project tackles a unique set of control problems for wastewater treatment, using NorthStar chemical products.

Amy's Kitchen

Load bank and automated equipment testing

This project wrapped up a wide variety of sensing and control technologies. Shown here is one of two control panels for monitoring and control of this system. The end-use application is proprietary.

The LabVIEW interface was a built executable that completed an extended, complex testing sequence with adjustable alarms and fault criteria for every variable recorded to data logs. The results of the testing were used for acceptance criteria for an external customer for the product.

A few details:

- Remote VFD control over Modbus TCP/IP with custom frame formats

- Nine RTDs read through custom driver board with filtering into analog inputs

- Three accelerometers read into analog inputs

- Two vibration sensors read into analog inputs

- Chiller flow rate sensors read into analog input

- Chiller/heater setpoint and monitoring over RS232

- Power supply monitoring over TCP raw socket

- Load bank control via control panel pictured, through PLC over Modbus TCP/IP

Kettle Foods

Remote temperature sensing and logging

This project involved monitoring solar modules out in the wild. The temperature was logged continuously at six points per node, with the deployment here comprising six nodes for a total of 48 sensors. These were all on a single bus, utilizing the 1Wire protocol to transmit temperature data over three wires over a distance in excess of 100m.

The sensor gateway was connected via VPN for web-enabled view and access of data from anywhere in the world. On top of this, Interface Innovations is able to continuously update, monitor and troubleshoot system performance on-call. Feature requests and additions were addressed in real-time.

Anemometer and pyranometer were later added with a DAQ for read inputs. Standard iicontrollibs and cupidweblibs were used for this project.

A few details:

- 100% Web interface

- Built-in power management board with backup Lipoly battery for backup in power outages and graceful shutdown when necessary

- Bus extendable (nearly infinitely)

- Individually addressable temperature sensors with unique ROM identifiers

- LED indicator status lights for field service

- Waterproof sensors accurate to within 0.5C, precision selectable 9-12 bits

- RF communication is an easy optional add-on for remote sensors in this configuration